GREENMAX Foam Compactor for Extruded Polystyrene Foam (XPS) Recycling

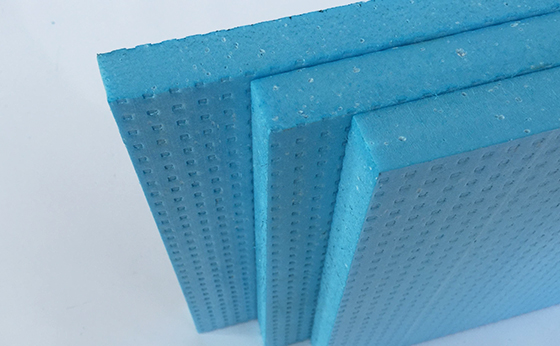

XPS (Extruded Polystyrene Foam), which is similar to EPS recycling, can also be recycled by mechanical recovery. XPS material is widely used as insulation material in the construction industry because it is moisture-proof insulation.Also, it can be used for furniture transportation as this material has antiknock quality. In addition, it is also used in crafts and model building, offers improved surface roughness and higher stiffness and reduced thermal conductivity.

Way to Dispose and Recycle XPS Foam:

GREENMAX foam compactor Apolo Series can reduce the volume of XPS waste up to 50:1. So the scattered and big size material can be compressed into tight blocks. Then the lightweight and scattered XPS will be easily transported.

GREENMAX foam compactor uses a more powerful crusher for XPS. Compared to the crusher of EPS, the crusher of XPS has double motor and more sharped blade. GREENMAX foam recycling machines can also handle this material effectively.

GREENMAX Foam Compactor Apolo:

GREENMAX foam recycling machine Aoplo Series machines can be divided into different models and each model have common points and also have some differences in use. The EPS and XPS handling is a good case that can show the use of different machine models. Machines can handle the waste polystyrene foam easily and effectively.

XPS Foam Compactor Operational Process:

The worker needs to put the XPS waste into the machine container and then the blade will crush the material into pieces with electrical power. Then the pieces will be compressed into a tight block under the pressure. Thus, at last, the incompact and big size XPS are compacted into regular and tight blocks.

Advantages of GREENMAX Foam Compactor Machine:

First, machines can help workers improve their work effects, then the work time can be saved. Also, their workload will be reduced.

Second, the machine owners can save their cost in labor and increase their benefits as the labor cost is reduced and the compacted XPS can be sold to buyers.

Third, the environmental pollution condition will be changed. The XPS waste is hard to decompose and it still has pollution even put into landfills. But compacted material can avoid the pollution problem to some degree. More, XPS waste can save raw material after being compacted and processing.

Successful XPS Foam Recycling Cases:

Initially confronted with an excess of waste XPS materials, Owens Corning sought external avenues for disposal, eventually turning to a granulating company for assistance. Through this partnership, affiliated with GREENMAX under INTCO Recycling, Owens Corning discovered a straightforward yet effective recycling solution. The introduction of GREENMAX foam compactor A-C200, provided a tailored remedy to their waste management challenges. This GREENMAX foam compactor efficiently reduced the volume of waste XPS, transforming it into recyclable materials suitable for granulation into various plastic products.

GREENMAX GREENMAX Apolo Series

GREENMAX Foam Compactor A-C300

Throughput 300kg/hCompression Ratio: 50:1

Compressed Density: 200-400kg/m3

GREENMAX Foam Compactor A-C200

Throughput: 200kg/h

Compression Ratio: 50:1

Compressed Density: 200-400kg/m3

Total Power Consumption: 19.55kw

GREENMAX Foam Compactor A-C100

Throughput: 100kg/h

Compression Ratio: 50:1

Compressed Density: 200-400kg/m3

Total Power Consumption: 10.25kw