GREENMAX Foam Recycling Machine

GREENMAX Machines was established in 2010. We focus on researching and developing the plastic foam recycling machine which is a kind of environmentally recycling system machine. With more than 15 years of accumulative innovation, GREENMAX factory now has machine APOLO, MARS, ZEUS, POSEIDON, TRITON, GAIA. We researches and produces foam densifier, EPS foam melting machine, dewatering machine, washing recycling system, pelletizing machine.

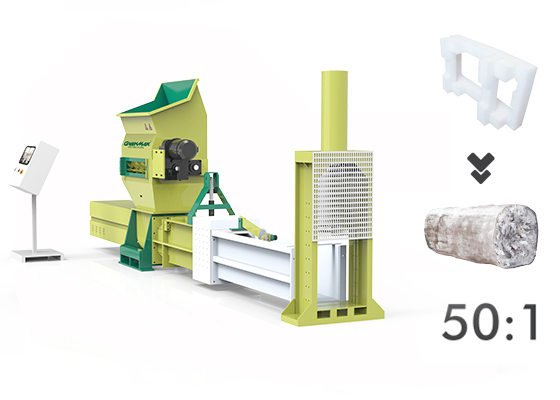

GREENMAX MACHINE APOLO SERIES:

GREENMAX foam compactor APOLP Series can compact all kinds of foam scraps and bulk foam scarps into a compact size. The compactor machine can compact the volume of Styrofoam as 50:1. It’s similar to make a laptop become a small key on the keyboard. And the compressed density of EPS scraps is 200-400kg/m3. The compact size of the EPS is easy to transport and store in a warehouse. What’s more, it is also applicable to materials including EPS, XPS, and PSP, like takeaway food containers and cups. The system of the Styrofoam compactor offers great convenience to you.

GREENMAX APOLO can comopact most PS foams including EPS, XPS and PSP.

GREENMAX MACHINE APOLO SILO SYSTEM:

GREENMAX FOAM HYDRAULIC COMPACTOR HERACLES

GREENMAX Hydraulic Compactor Heracles Series is an EPS recycling machine specialized in compressing waste foam into blocks by hydraulic pressure without heating. Waste foam can be crushed and then compacted into blocks with a high volume reduction ratio, greatly reducing the volume of waste foam, and saving storage and transportation costs.

It can deal with foam such as EPS packaging, EPS DUST, PU, and EPP.

GREENMAX MACHINE TRITON RECYCLING WASHING SYSTEM:

GREENMAX recycling washing system Triton is an foam recycling system for contaminated foam waste. foam waste will be crushed into small scraps then washed and dried, finally it will be compacted into blocks. GREENMAX Triton recycling machine can help to deal with garden trays are made of EPS and other plastic material such PE film, PP Film, HDPE, PP.

GREENMAX MACHINE MARS SERIES:

GREENMAX foam densifier MARS Series provides a great method to waste foam recycling. GREENMAX Mars Series melting machine is a big scale machine for waste foam such as EPS recycling. foam densifier mainly for the expansion characteristics of foam. This machine has a built-in rotary cutter and hot-melting wire rod. It is first crushed into foam by a cutter and then heated by a hot melt screw at a high temperature. After melting, Foam will flow out like water, but after cooling, it will be as hard as a solid brick. We call it foam ingot.

The volume ratio of foam ingot to foam waste can reach 90: 1, saving a lot of storage space and transportation costs. foam densifier applicable materials are various, including EPE foam, EPS, EPP, and so on. GREENMAX foam densifier Series is developed to recycle such waste foam and make profits for your business.

GREENMAX MARS was designed for Hot Melting plastic foam like EPE, EPP, EPS, XPS and PSP.

GREENMAX MACHINE ZEUS SERIES:

GREENMAX foam compactor ZEUS Series is specially designed for Expendable Polyethylene (EPE) with surface melting technology which can perfectly solve screw compression issues. And the compacted foams inside wouldn’t expand again. Also, ZEUS Series can handle EPS, XPS, and PSP efficiently and environmentally. The throughput of this compactor is 100kg/h and it can compact foam as a ratio of 50:1. And the compressed EPS&EPE density is 200-400kg/m³. So that the waste foam materials can be transported much more easily.

GREENMAX ZEUS can process a wider range of foam materials, such as EPE, EPP, EPS, XPS and PSP.

GREENMAX MACHINE ZEUS SILO SYSTEM:

GREENMAX MACHINE ZEUS WITH AUTO CUT-OFF:

GREENMAX MACHINE POSEIDON SERIES:

GREENMAX dewater machine Poseidon series was designed to compact plastic containers like PET bottles, aluminum cans, etc. GREENMAX Poseidon series process the vast majority of beverage packaging. It is an efficient recycling machine for some manufacturers.

Poseidon series is specialized in de-watering and compacting beverage bottles and packaging recycling. Poseidon de-water helps dry PP/PE film flakes after the cleaning line and helps screw out water in containers. Applicable materials include PET bottles, aluminum cans, PP/PE films, beverage cartons, and yogurt cups.

GREENMAX POSEIDON was designed to Dewater & Compact packaging and containers (PE/PP Film, PET bottles, aluminum cans, beverage cartons and yogurt cups, etc.)