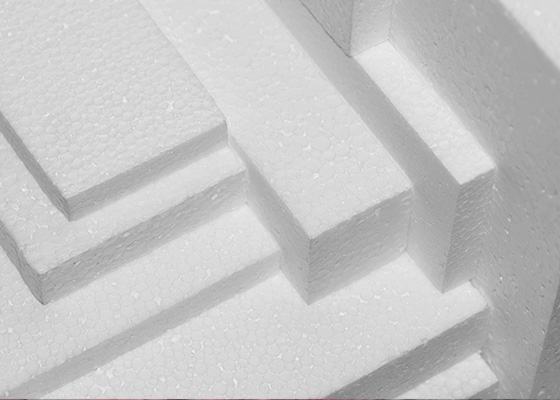

What is Polystyrene Off cuts?

Polystyrene has a good function in many fields, such as EPS. Many EPS factories manufacture EPS boards in building and art industries. After the workers processed the polystyrene foam, there are so huge number of waste polystyrene off cuts left.

If these polystyrene off cuts are thrown away, on the one hand, it is so pitiful to waste resources, on the other hand, for EPS factories, at the same time, they would also have some low-quality products that are unable to be sold out.

In this situation, so EPS factories usually choose to recycle these waste EPS boards to reuse them for other products.

The advantages of Polystyrene Off cuts Recycling:

1.Selling to make money2 reducing resources waste

3 protecting the environment

4 saving transport and labor cost

5 saving Storage space

How to recycle Polystyrene Off cuts?

GREENMAX recycling bought and collected waste Polystyrene Off cuts from the EPS factories who want to recycle so great number of waste EPS Off cuts boards, thereby extending the second life of the Polystyrene Offcuts.

A. Cold Pressing

GREENMAX Recycling machine compactor APOLO Series could compact waste Polystyrene Offcuts into blocks by a series of process such as crushing ,compacting and extruding, and the tight compacted EPS blocks are much easier to handle and can be granulated.

Another set of GREENMAX Recycling machine densifier MARS Series is also applied to EPS Offcuts recycling. After a process of shredding, heating, and extruding, the EPS Off-cuts boards become the densified PS into blocks like stone, and volume reduction ratio up to 90:1.