With the development of technology GREENMAX may develop newer foam recycling machines to deal with PU foam

Originally developed to address a scarcity in the 1930s, polyurethane (PU) is now a vital component of many industries, including cushioning and insulation. PU was first created in 1937 in Germany by Otto Bayer and his colleagues as a low-cost, multipurpose substitute for rubber. Because of its powerful bonding and protecting qualities, it gained popularity in coatings and adhesives quite fast.

In industries including refrigeration, automobile, and construction, rigid polyurethane foam has become indispensable. It is utilized in panels and boards used in building to control indoor temperatures and save energy consumption. It is utilized in bumpers, seats, and internal components in the car industry because of its light weight and energy-absorbing qualities, which increase safety and fuel efficiency. It is essential for improving energy efficiency in refrigeration by providing thermal insulation for freezers and refrigerators.

.jpg)

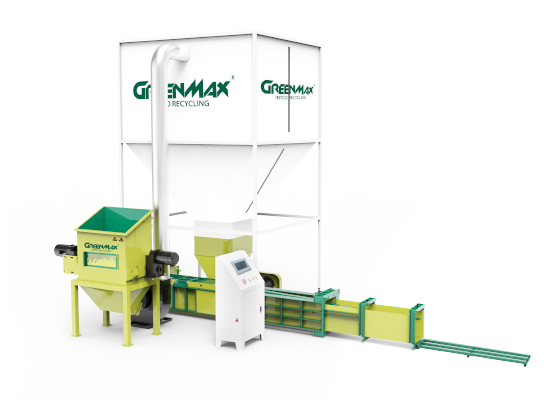

Unfortunately, the current global treatment of PU foam is not very optimistic, but the amount and wide range of use of this material are not low. Many customers have consulted GREENMAX about the recycling of PU foam. Currently, for hard PU foam, we have two main foam recycling machines, one is a foam crusher with only crushing function, and the other is a hydraulic foam compactor with both crushing and compression functions. However, for softer foams such as those in sofas, only foam crushers can be used for crushing. At present, GREENMAX has helped several customers from all over the world to basically successfully recycle PU foam.

"Despite its versatility, polyurethane foam presents significant environmental challenges due to its non-biodegradable nature and high durability. Millions of tonnes of rigid polyurethane foam are produced each year, with the majority ending up in landfills. In construction, spent foam from sandwich panels creates waste both during production and on-site. Globally, end-of-life polyurethane foam waste is estimated to be between 1 million and 1.3 million tonnes per year, primarily from building insulation panels and refrigeration units."

GREENMAX is also constantly trying to design and manufacture more types of foam recycling machines to help recycle PU foam to reduce environmental pollution. If you have a better recycling method, you are welcome to contact GREENMAX at any time!