Using foam compactor recycling may solve the problem of expensive EPP raw materials

It is anticipated that the worldwide market for EPP foam packaging would grow to a GDP of USD 365.5 million by 2024. Looking ahead, it is projected that this market would reach USD 496.1 million by 2034. The market for EPP foam packaging is anticipated to grow at a CAGR of 3.1% over the course of this projection period. Several obstacles confront the EPP foam packaging sector. Relatively high production costs in comparison to alternative packaging materials are one of the main obstacles. EPP foam is manufactured using high-tech equipment and sometimes-expensive raw materials.

EPP is a relatively expensive raw material, but it has become an increasingly common packaging material, so we should recycle it. This is equivalent to saving the investment cost of materials, because the recycled EPP foam can be sold and manufactured into a variety of new plastic products. Recycling EPP foam is definitely a project worth investing in, because the world now discourages random discarding or landfilling of foamed plastic products such as EPP, which not only causes environmental pollution, but also takes up a lot of land resources, so The best way is to turn waste EPP into treasure.

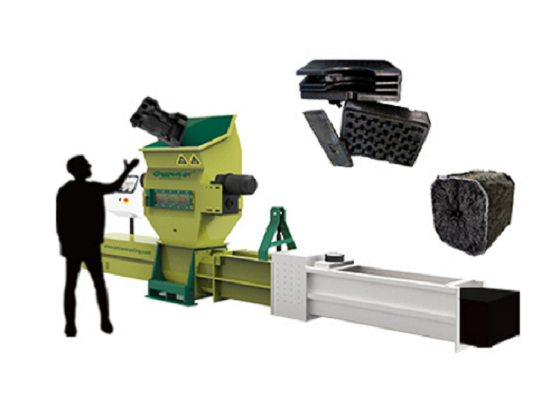

If you want to recycle EPP foam, you can use appropriate recycling equipment, such as the GREENMAX foam compactor Zeus series. This equipment is specially designed to recycle EPS and can recycle both EPE and EPP foam. GREENMAX recycling equipment can generally recycle a variety of foams. The GREENMAX foam compactor Zeus series can compress EPP foam to 1/50 of its original volume.

The competitive landscape in the EPP foam packaging market is changing. Leading companies like Germany's BASF and Germany's Knauf Industries are leading the way with their powerful brands and extensive worldwide reach. With an emphasis on lightweight and fire-retardant solutions for automotive applications, BASF is constantly improving its EPP product portfolio. In contrast, Knauf Industries is increasing its manufacturing capacity in order to meet the growing demand in the consumer goods and electronics industries.

There are also companies in the automotive industry that cooperate with GREENMAX and recycle by using foam compactor. Because EPP is light in weight, it is not only used in the packaging of auto parts, but is also used as a raw material for auto parts to reduce vehicle weight, such as seats and bumpers. If you also have relevant industry recycling information and foam compactor, you are welcome to share and discuss with GREENMAX at any time. Together, we will actively help EPP recycling achieve globalization!