The recycling demand and technology of polypropylene with the foam compactor have entered a new era in Japan

The recycling demand for Foam is constantly expanding, and recycling technology is constantly innovating. Especially for some foam types whose recycling technology was relatively less mature a few years ago, there are now better solutions.

Expanded polypropylene particle foams are being offered by JSP, a thermoplastic foam expert and raw material manufacturer based in Japan. In an effort to "relieve the burden on the oceans," vice president of sales Frank Tölle recently announced the addition of Arpro 35 Ocean to the portfolio. This is the first EPP product to incorporate recycled content obtained from marine garbage.

In fact, used expanded polypropylene can also be recycled. After being used once as a single raw material, it can be continued to be used as recycled material. Before use, it needs to be compressed first. Like expanded polystyrene, whenever "Expanded" is mentioned, it proves that this material has been foamed. All foamed plastics need to be compressed first. Recycle, otherwise it will cause unnecessary trouble.

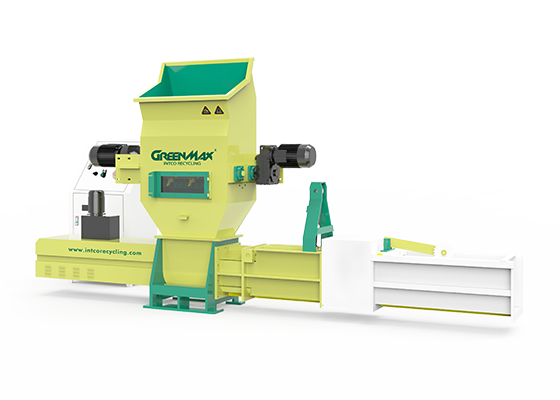

Recycling using the GREENMAX foam compactor Zeus series is one of the many recycling methods. This equipment uses cold pressing technology to help with recycling. Like all recycling equipment, the pre-processing method is the same. First, the foam compactor's crushing chamber will process the expanded polypropylene foam. After crushing, it will enter the second step of recycling, which is screw extrusion. After screw extrusion, the entire compression process does not end. Expanded polypropylene foam is a type of foam with higher hardness. At the discharge port of the equipment, we installed a hot melt ring to heat the surface of the blocs to compress the material more tightly and prevent the material from being bumped during transportation. become loose.

According to JSP, its carbon footprint is smaller as during production of the new foam, 7% less CO2 is produced compared to conventional foam. The company mainly adds marine debris as recycled material to expanded polypropylene foam, while GREENMAX provides The foam compactor turns used expanded polypropylene foam into a precious raw material, both of which can effectively reduce carbon emissions and contribute to micro-environmental protection.