Nokia fulfills its environmental mission by replacing EPE packaging - Foam pelletizer can process post-use EPE

As companies strive to make their packaging more sustainable, circularity (recyclability, reusability) is often where they are now working.Nokia's most recent revamp of the packaging for its Fixed Networks Lightspan line, which is sold to Deutsche Telekom. Because Nokia's new compact package is 44% lighter and 60% smaller than its prior pack, it saves packaging waste. The company claims that this lowers the line's CO2 emissions by as much as 60%.

The person in charge of the company said that in the past, EPE foam was usually used to help products create shock-absorbing packaging, but now degradable and sustainable materials are being used for packaging: the current solution is to use polyester made of natural compounds, such as acrylic. Lactide (LA), glycolide (GL) and ε-caprolactone (CL). They are also exploring other materials with suppliers.When no longer needed, it can be disposed of as organic waste, broken down into water and carbon dioxide with the help of soil microorganisms. Does this really mean that EPE foam packaging will completely disappear from this earth? The answer is no. In fact, this is unrealistic because the scope of use of EPE foam packaging far exceeds our imagination.

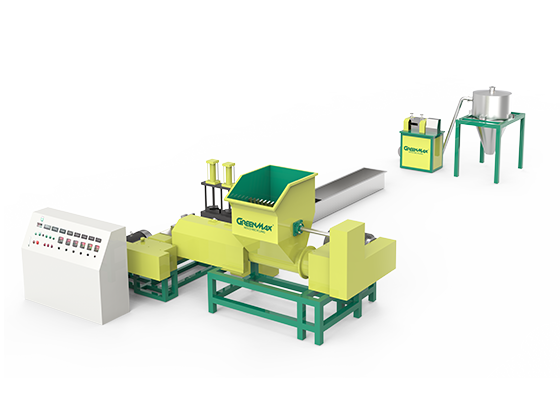

When it comes to EPE foam being non-degradable, there is really no need to panic because even though this kind of packaging is non-degradable, it is 100% recyclable. As long as you do not discard it randomly and follow reasonable recycling procedures, you can well avoid the pollution of EPE foam waste. GREENMAX initially provided equipment to help compress waste EPE foam. In recent years, GREENMAX has designed and manufactured foam pelletizer to directly realize granulation. If you have granulation needs, you can skip the compression step and directly achieve granulation. The loose EPE foam is put into the foam pelletizer, crushed and melted, and then extruded and drawn. These drawn EPE strips are cooled by the water in the sink, then automatically cut and air-dried, and finally collected into a bag to achieve granulation.

If you are interested in the recycling of EPE foam, you will find that there are more ways to recycle EPE foam than the one we mentioned above, so there is no need to worry and be frustrated that EPE foam cannot be degraded. If you have other questions about recycling For questions and needs about EPE foam, please feel free to consult GREENMAX!