Mechanical recycling—Polystyrene densifier occupies a major position among many recycling methods around the world

A common plastic that is neither biodegradable nor essentially recyclable when combined with other elements is polystyrene. A German research team has presented a biohybrid catalyst that oxidizes polystyrene microparticles to promote their subsequent decomposition in the journal Angewandte Chemie. Polystyrene The probability of appearing in our daily life is very high. For example, yogurt and some daily plastic products are made of hard polystyrene plastic. Inflated expanded polystyrene is also a very common material. In recent years, domestic waste Among them, the proportion of expanded polystyrene is gradually increasing, and the recycling method of this material has become the main research object.

A major disadvantage of polystyrene is its poor biodegradability, which leads to environmental pollution. Polystyrene is recyclable when clean and not mixed with other materials, but not when it is contaminated or mixed with other materials. This is a serious loss for both polystyrene itself and other recyclable materials. We can have many ideas for resource recycling. In addition to degrading and decomposing polystyrene, are there other feasible ways?

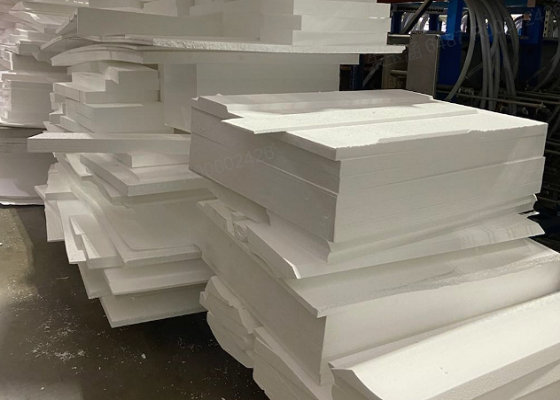

The process of recycling polystyrene using chemical methods is complex and energy-consuming, and cannot be widely used in a short time. Although we support the diversification of recycling methods, considering the current actual situation, mechanical recycling is more likely to be used by most people. Recycling requirements are accepted by the factory.

We usually recommend using polystyrene recycling machines to prevent waste from being landfilled and incinerated, causing soil, air, and a series of other pollution. At present, polystyrene densifier has a relatively high compression ratio. The polystyrene densifier produced by GREENMAX can have a compression ratio of 90:1 and uses hot melt technology. Since last year, hot melt technology has been pushed to the forefront, saying that it is not an environmentally friendly recycling method because it produces smell during the melting process of polystyrene. However, to address this problem, GREENMAX has already developed a polystyrene densifier based on the original polystyrene densifier. Improvements were made to resolve this issue.