Foam recycling is ongoing in Van Buren and will be better in 2024 with hydraulic compactor

According to the Van Buren Conservation District, recycling was quite active in 2023. According to recycling coordinator Kalli Marshall, they have two drop-off locations open year-round and host recycling events every year. In 2023, the program expanded to include new services such battery collection and foam recycling at nine locations around Van Buren County. The Resource Recovery Program is supported by the counties' townships, and this year's expenses exceeded $235,000. In the past year, the foam recycling project has also been a breakthrough.

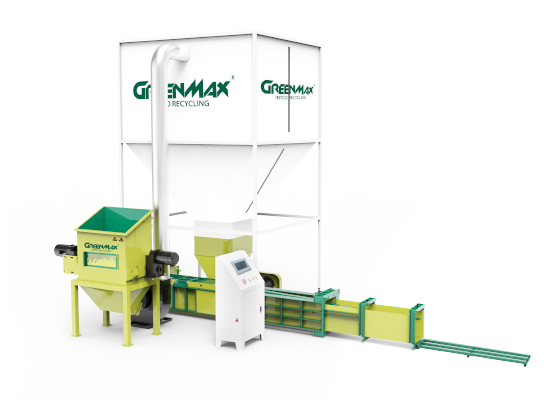

As the times evolve, recycling equipment must also continue to advance. With the recycling needs of the market and the recycling needs of customers, GREENMAX foam recycling machine is also constantly updated and iterated. When it comes to the new foam recycling machine, we will definitely think of the hydraulic compactor. This equipment is different from GREENMAX's previous compression equipment. It does not recycle through screw extrusion or hot melt technology, but through hydraulic technology. The two most significant features of this hydraulic compactor are: on the one hand, it combines the advantages of cold pressing technology and hot melt technology, and on the other hand, it increases the types of recyclable materials.

How does Hydraulic compactor combine the advantages of cold pressing technology and hot melt technology?

In the process of recycling waste foam, the hydraulic compactor can achieve a compression ratio of 70:1, while the GREENMAX foam compactor with cold pressing technology has a compression ratio of 50:1, and the foam densifier with hot melt technology has a compression ratio of 90:1. The Hydraulic compactor uses less electrical energy to achieve a compression ratio somewhere in between. The compression ratio of the Hydraulic compactor is higher than that of cold pressing technology, and its energy consumption is lower than that of hot melt technology. It can be regarded as an efficient and environmentally friendly equipment.

What materials can the Hydraulic compactor recycle?

In the past, foam recycling machines were helpless with foams such as PUR and PIR, and it is precisely because of the advent of Hydraulic compactor that these two materials have become recyclable. This can also be regarded as a breakthrough in the field of recycling. When each new foam uses the recycling solution, this non-renewable material causes less pollution to the environment.

The person in charge of the region said that this recycling of foam, discarded electronic products, and household waste will continue in 2024, and the pace of waste recycling will never stop.