Foam compactor will help more people realize the recyclability of XPS foam

The Créastyr project is a project carried out by the plastic packaging company Elipso Alliance and the European representative of EPS manufacturers Eumeps to recycle EPS foam and XPS foam. The event plans to achieve 100% recycling of EPS foam and XPS foam in France by 2025. This ambitious plan began in France last year and will gradually be implemented throughout Europe.

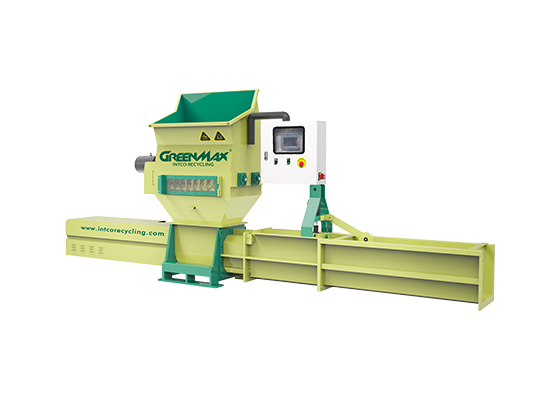

We are already familiar with EPS foam packaging, but are you familiar with XPS packaging? In fact, the raw materials of these two foam packaging are PS. It's just that the processes used in the production process are different. We can simply think that EPS uses a foaming process, while XPS uses an extrusion process. Recycling XPS foam is also one of the main recycling businesses GREENMAX engages in. In recent years, the demand for XPS foam recycling has also been increasing. One thing to note is that the two types of PS foam are structurally different: EPS is composed of beads, while XPS is foam. The two have complementary functions. Currently GREENMAX foam compactor can help recycle XPS foam.

At present, we have successfully helped a recycler in Europe to recycle. This customer mainly produces EPS fish boxes and XPS waste foam. After the advice of GREENMAX engineers, they chose the foam compactor A-C 200 to recycle these two materials at the same time. There are 2 tons of EPS and 1.5 tons of XPS every month. Before using the foam compactor, it was burned, but in response to the government's call. Start using foam compactor for compression and recycling, an environmentally friendly recycling method. The GREENMAX foam compactor can achieve a compression ratio of 50:1 and is designed to squeeze out the air in foam including XPS.

The recycling of XPS should not receive much attention and promotion. The current recycling rate is far from enough. We should let more related industries understand the foam compactor and use it to create a green recycling environment.