Foam board insulation is used and recycled in the construction sector - Foam compactor as the main "supporter" of recycling programs

Foam plastic has been favored by many fields because of its various excellent properties. Today GREENMAX will introduce you to foam plastic in this article, especially the application of EPS foam plastic in thermal insulation performance. You must often see food packaging in life. Fresh food packaging uses ESP foam plastic. This is precisely because this material has better performance in maintaining temperature. Whether it is maintaining a lower temperature, such as packaging for cold chain transportation, EPS boxes for fresh fish; or packaging that maintains a higher temperature, such as packaging for insulated lunch boxes and EPS coffee cups. Not only can we see the application of this material in the food field, foam board insulation is also often used in the construction industry.

Foam board insulation is often used in the infrastructure construction of houses. The foam board insulation usually have fixed sizes and are cut into regular rectangles with regular thickness and size during the production process. The application of EPS in the construction field effectively solves the problem of winter insulation in cold areas.

Is it safe to use foam board insulation?

Many people believe that EPS foam is filled with air and is a flammable product, and they have deep doubts about the safety of foam board insulation in residential applications. In fact, this is nothing to worry about. The EPS materials used in foam board insulation usually add a certain proportion of flame retardants. Also for fire protection and aesthetic reasons, any foam board insulation needs to be covered with masonry plaster.

Does Foam board insulation need to be recycled?

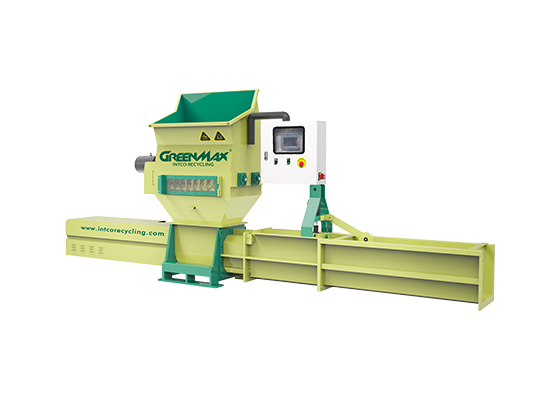

Foam board insulation needs to be recycled. Because EPS foam plastic is a non-degradable material, it needs to be recycled, especially the scraps generated in the manufacturing process of foam board insulation, as well as defective products produced during the production process, all need to be recycled. Usually, in order to reduce the volume of foam board insulation and facilitate recycling, relevant companies will choose to use foam compactor to compress it first and then recycle it. The compression ratio of foam compactor is usually 50:1, which can effectively reduce the volume of foam board insulation.

If you want to know more about foam board insulation recycling, you can consult GREENMAX at any time.