EPS Waste Recycling In The United States

EPS foam is a thermoplastic material, per cubic meter volume contains 300-600 million independent airtight bubbles, the volume of air contains 98% or more. Due to air thermal conductivity is very small, and is closed in the foam, the air can not be convection, so EPS is a very good material with thermal insulation properties.

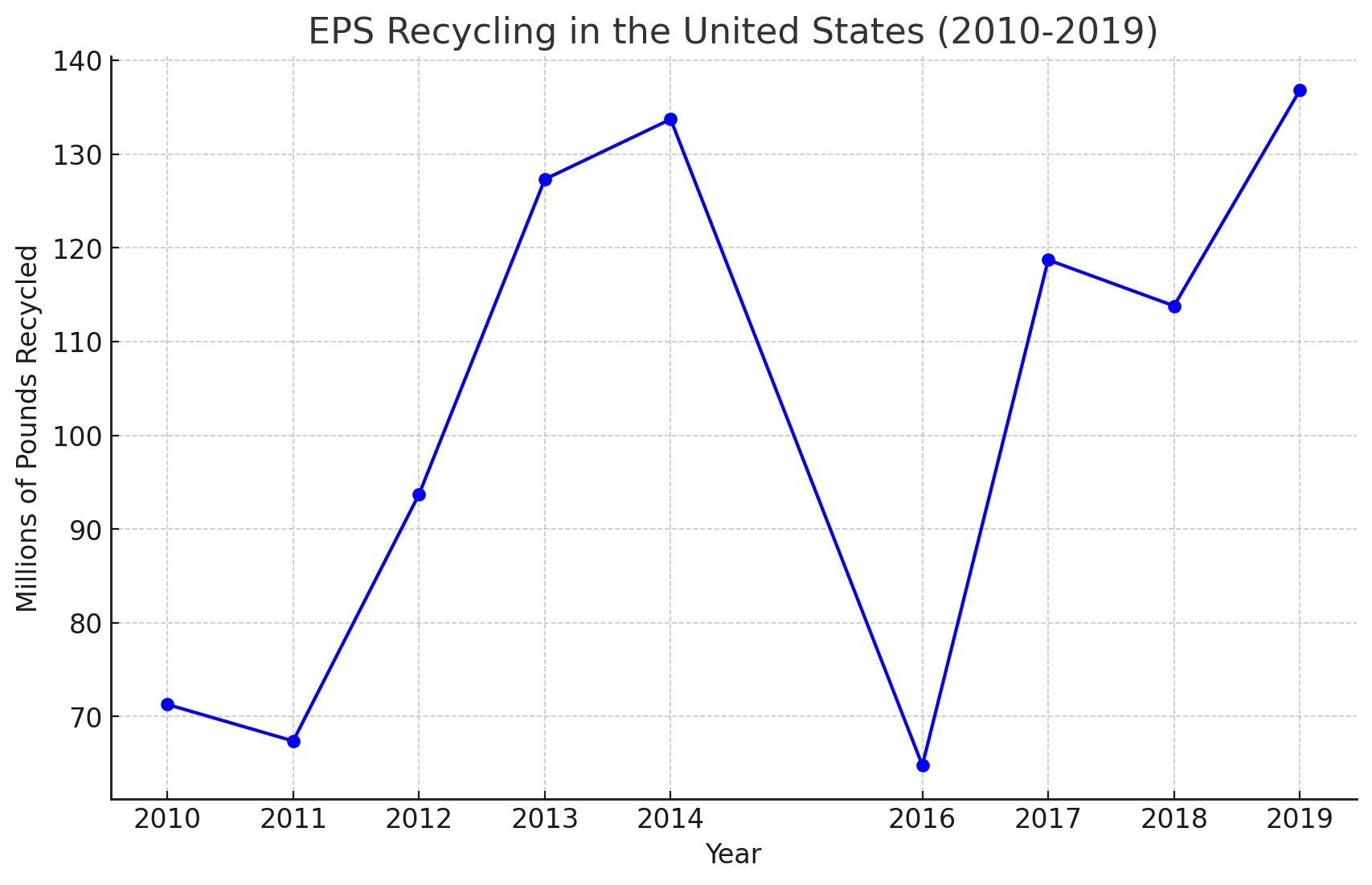

From 2010 to 2019, with 136.8 million pounds recycled in 2019. It highlights the fluctuating but overall positive trend in EPS recycling over the years. On average, 56% of post-use EPS is used as recycled content in new packaging. The recycling process includes collection, regrinding or reprocessing, and molding and production, all contributing to the circular economy. EPS is reused in various ways, such as in molded EPS pallets for car parts, which can be used up to 24 times, and in reusable temperature-controlled shippers. These reuse methods demonstrate the material's durability and sustainability.

Foam densifier is able to reduce the volume of EPS foam significantly. GREENMAX foam densifier compresses the foam, reducing its size by up to 90:1. This process is crucial because EPS foam is lightweight but takes up a lot of space, making it inefficient and costly to transport without prior volume reduction. Foam densifier works by applying heat to melt the EPS foam. As the foam is melted, it turns into a dense material, often referred to as "EPS ingots." These ingots are much smaller and denser than the original foam, making them easier to store and transport.

GREENMAX foam densifier plays a crucial role in the recycling of EPS foam by making the process more efficient and environmentally friendly. By converting bulky, hard-to-manage foam into dense, reusable material, these machines help close the loop in the EPS recycling process, contributing to a more sustainable and circular economy.