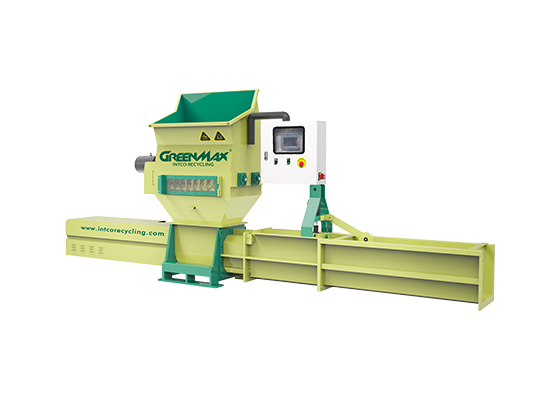

EPS from discarded helmets can be compressed and pelletized with an EPS screw compactor

At the EPS Expo in Orlando, Florida, in March, Epsilyte, a manufacturer of insulative materials with headquarters in The Woodlands, Texas, was presented with the Excellence in EPS Recycling award. The prize honors exceptional accomplishments in foam recycling as well as advancements in innovation and technology. Chad Zielinski, Director of Research at Epsilyte, works to recycle EPS in helmets! Because the helmet protects the wearer in the event of an accident, Epsilyte says it knows there will be no compromise in quality when adding recycled content to the EPS used in the helmet liner. Zielinski designed a solution to include 50 percent recycled content in these applications without sacrificing quality, the company said. Currently using EPS recycled materials is a trend in the recycling field.

.jpg)

Can the EPS foam recovered from helmets only continue to be used to make helmets? Of course not, EPS recycled material can be added to many new plastic products, one of the more popular EPS recycling system is to use EPS screw compactor to compress EPS first, and then granulate the compressed EPS, which is compressed by GREENMAX The volume of the original EPS becomes 1/50 of the original volume, and the volume has been significantly reduced. Only in this way can the subsequent recycling process be facilitated. EPS screw compactor is usually also called EPS cold compactor, and the whole process uses screw extrusion without heating at all. Lay the foundation for the entire EPS recycling system

The EPS blocs compressed by the EPS screw compactor will be purchased by downstream buyers at a very good market price and used to make plastic particles. The activity of granulation is being carried out in many countries, that is to say, you can conduct international trade by selling compressed EPS blocs, among which GREENMAX not only provides recycling equipment, but also buys back EPS to help you assemble a complete EPS recycling system. GREENMAX uses EPS to make plastic particles, and then makes frames, including photo frames, mirror frames, picture frames, and even skirting boards used in interior decoration, and recycled materials can be added to them.