EPS compactors can be used to recycle EPS and save human health

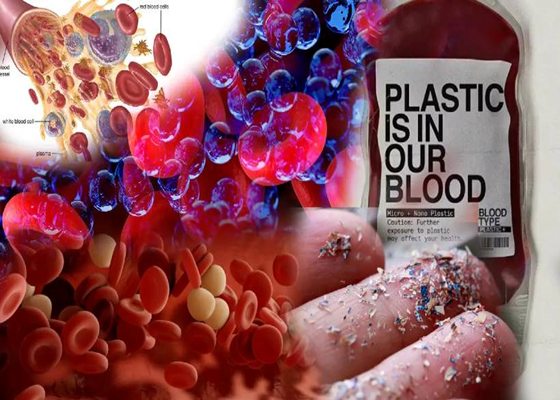

Dr. Alice Houghton, of the UK's National Oceanography Centre, said: "This is a worrying finding, as microplastics have been shown in the laboratory to cause inflammation and cell damage. This research proves that plastic particles are not only found throughout the environment, but also in our bodies. The long-term consequences of this situation are not yet known. " Microplastics from EPS are one of the main sources of blood contamination, all because of the wrong way of recycling EPS that leads to microplastics entering the ecosystem.

Washington residents threw out 12,890 tons of EPS foam packaging in 2017, As of mid-2021, Washingtonians generate about 23,000 tons of EPS foam garbage each year, with just 3% of it getting recycled, according to the Washington Department of Ecology. In just 4 years, EPS usage has doubled and only 690 tonnes have been properly recycled. It can be seen that the form of EPS recycling in the United States is not optimistic. Correct recycling should be carried out in time to avoid harm to the human body caused by microplastics. EPS compactor can prevent waste EPS from flowing into the natural environment and the biological chain.

The EPS compactor is now widely used in the EPS recycling market in the United States and even around the world, and mechanical recycling is nothing new. Some American companies have cooperated with GREENMAX for a long time and successfully carried out recycling work with the EPS compactor.

GREENMAX has a guest who is engaged in agriculture and expects to generate 3,000 tons of EPS waste this year. He hopes that GREENMAX can provide a good solution. Because the customer also has granulation needs, after a high degree of customization, GREENMAX provided the customer with an EPS compactor A-C300 equipped with a conveyor belt and part of the granulation device. The customer is very satisfied with this EPS compactor. He is also proud of his contribution to the environment.