The Introduction Of Polystyrene

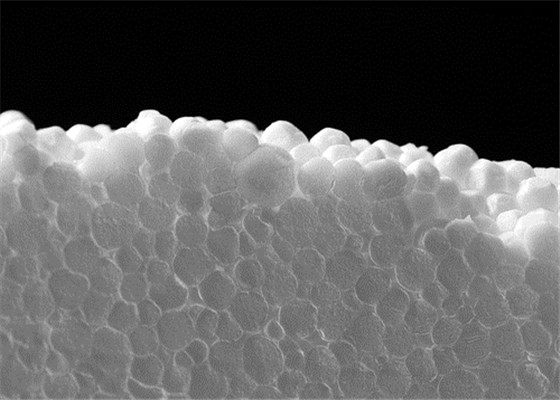

Polystyrene particles called the expanded polystyrene foam pellets. The material is made from based raw materials of expanded foam. Polystyrene particles is the main aggregate pellets of polystyrene insulation mortar.

The material is suitable for building energy efficiency by 50% and 65% of the target of the new requirements, within the expansion and renovation of the existing building industrial and civil buildings facades, external insulation and household walls, basements, garages, stairways, corridors, fire exits, hot bridge alone insulation, EPS, XPS leveling fire or protective layer .

Since the material itself material reasons, are flammable insulation materials, fire-retardant grade can reach B2 level.

The material is suitable for building industry and achieved energy efficiency by 50% and 65% of the new requirements, within the expansion and renovation of the existing building industrial and civil buildings facades, external insulation and household walls, basements, garages, stairways, corridors, fire exits, hot bridge alone insulation, EPS, XPS board leveling fire or protective layer, etc; building height is not more than 100m.

Advantages: insulation effect is good and cheap.

The relative density of the polystyrene is only worse than PP, PE, having excellent electrical properties, particularly good high frequency characteristics. In addition, is only worse than the methacrylic resin in light stability, its anti-radiation ability is the strongest in all plastics. The most important feature is that polystyrene thermal stability and fluidity is very good when melted and easily to mold especially injection molding. They are suitable for mass production with good molding shrinkage and dimensional stability.

Polystyrene molecular is too high, is difficult to process, the molecular amount is usually used 50,000 to 200,000 thermoformed polystyrene. With increasing temperature, rigidity (modulus of elasticity, tensile strength, impact strength) is down and large elongation at break.

Polystyrene (PS) included GPPS, expandable polystyrene (EPS), high impact polystyrene (HIPS) and syndiotactic polystyrene (SPS). GPPS is non-toxic, colorless and transparent pellets, like glassy brittle material, its products have a high transparency, light transmission rate is up to 90%, good electrical insulation properties, easily to color processing, good rigidity and good chemical resistance. Deficiencies of GPPS are brittle, low impact strength, prone to stress cracking, poor heat resistance and intolerance boiling water.